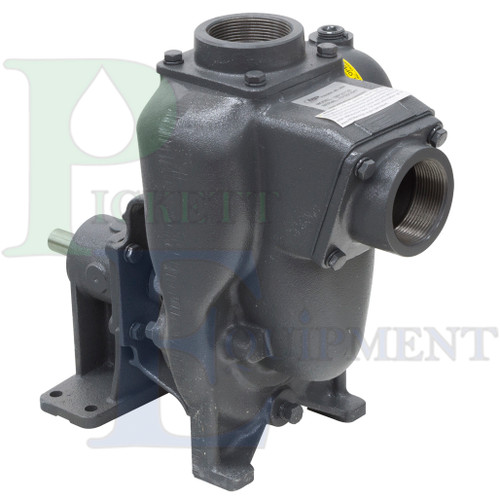

Description

2” ductile iron pump, aluminum impeller and wear plate. Suitable for pumping Jet-A and gasoline when coupled to explosion-proof motor, but not UL approved. Comes mounted on a bearing pedestal, or long-coupled to a 3HP 1PH explosion-proof motor. Features include:

- MADE IN THE USA!

- Viton elastomer seal with stainless spring & carbon/silicon carbide seal faces

- Stainless impeller sleeve

- Up to 130GPM

- Can swap flanges to 1-1/2”, allowing up to 85GPM

- Max 12’ suction lift. A foot valve is recommended to help keep prime

- Internally bypassing at roughly 40PSI so it won’t blow a hose apart

- Priming plug to purge all air from pump bowl to ensure seal longevity

- Drain plug for easy winterization

- Removeable flanges to enable ease of removal in hard pipe installations

- Self-priming, but does not use a suction flapper. A check valve is recommended to help maintain pump prime.

- Cork flange gaskets for long life in fuel service.

- Non-sparking impeller collar

- 1-year warranty on Baldor motors. More info available under Warranty tab

- 1-year warranty on pump defects. Leaking seal, or damage due to misuse is not covered under warranty.

- Motor is explosion proof

Cautions:

- Not UL-approved. UL-approved units available.

- Do not run pump dry. Wet seal pumps available under our DWS line.

- Pump suction must be the same size or larger than the discharge! If discharging 1-1/2”, you must use 1-1/2” or 2” suction. Failure to follow proper pipe sizing will result in cavitation, which will lead to pump failure and is not covered under warranty.

Plumbing tips:

- To maximize your pump’s capability, use as few 90° elbows as possible. This is especially important on the suction side of the pump.

- These self-priming pumps are designed to provide high flow, but they like to push liquid, rather than pull it. You can maximize your pump’s performance by keeping the suction line as short, and as straight, as possible.

- 90° elbows are unavoidable. However, we highly suggest using long sweep elbows instead of hard 90° elbows.

- Here’s an example of how badly 90° elbows can affect your flow. In 3” line, every 90° elbow is equivalent to adding an extra 11’ of line. A sweep elbow, however, adds about 8’. A 45° elbow adds 4’ of line. So, if you add 5 90° elbows, you’ve added 55’ to the suction line. By adding that many elbows, you drastically reduce the pump’s efficiency.

- If you have to have numerous elbows, it is recommended you increase your suction line by one pipe size (from 2” to 3”, or from 3” to 4”). Also, be sure to run full port valves and tank fittings. Any restrictions in the suction line will hamper performance. You can only flow as fast as your smallest restriction.

- Most self-priming pumps are designed as internally bypassing, meaning a discharge bypass is not needed. However, it is recommended that you avoid slamming the discharge valve shut, as this can cause a water hammer effect, which can result in seal failure.

Pump is available with these variants:

35728: 2” ductile iron pump with bearing pedestal. Stainless fasteners and quality anti-seize used in assembly.

35728-31: 2” ductile iron pump with 3HP 1PH 115/230VAC Baldor Class I, Group D, Division 1 electric motor, mounted on a base plate. Motor and pump are long-coupled via Lovejoys. Motor is single speed, and rotates at 3,450RPM. To “slow down” pumping, you may slightly close/throttle back the discharge valve. Stainless fasteners and quality anti-seize used in assembly.